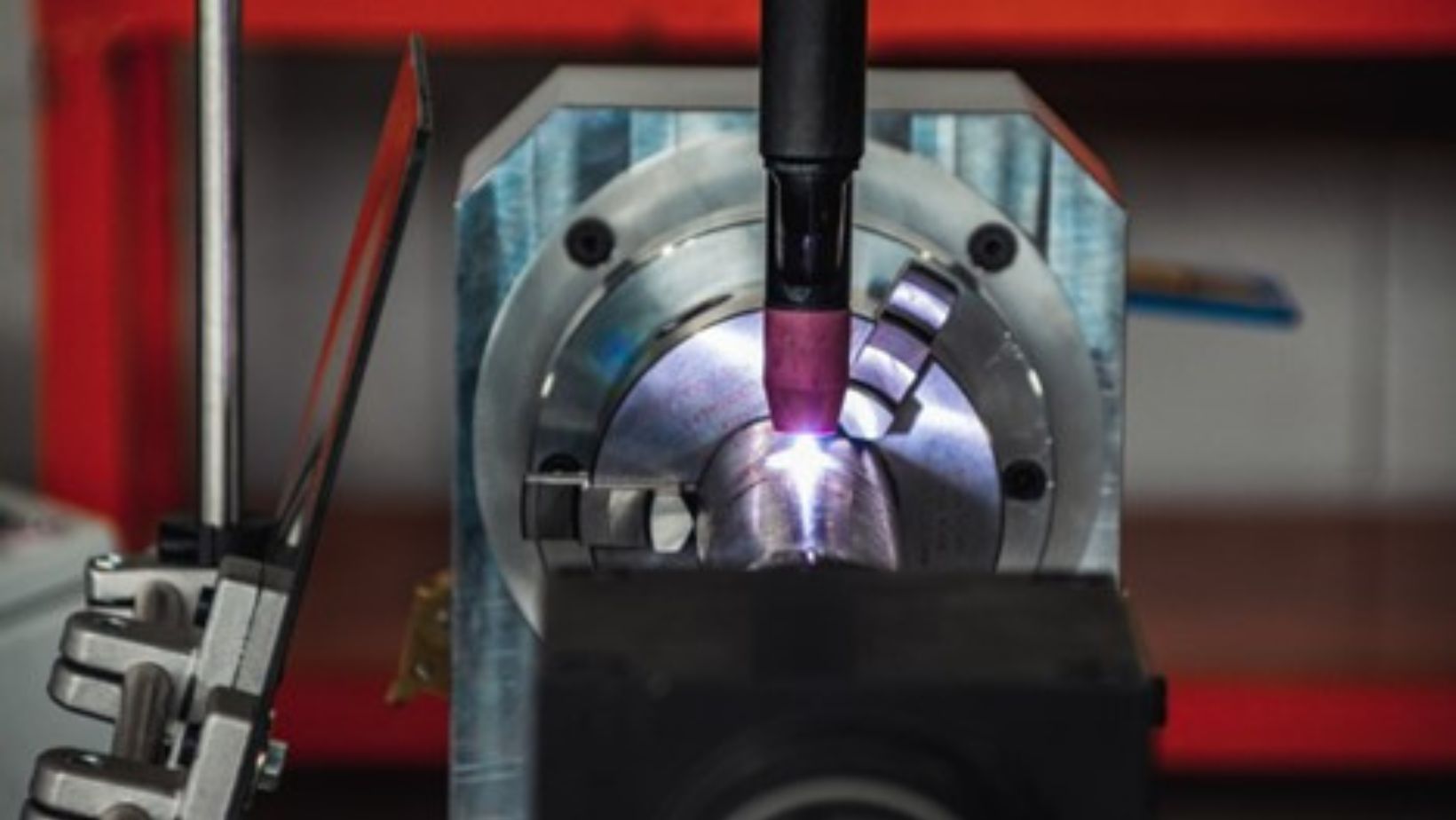

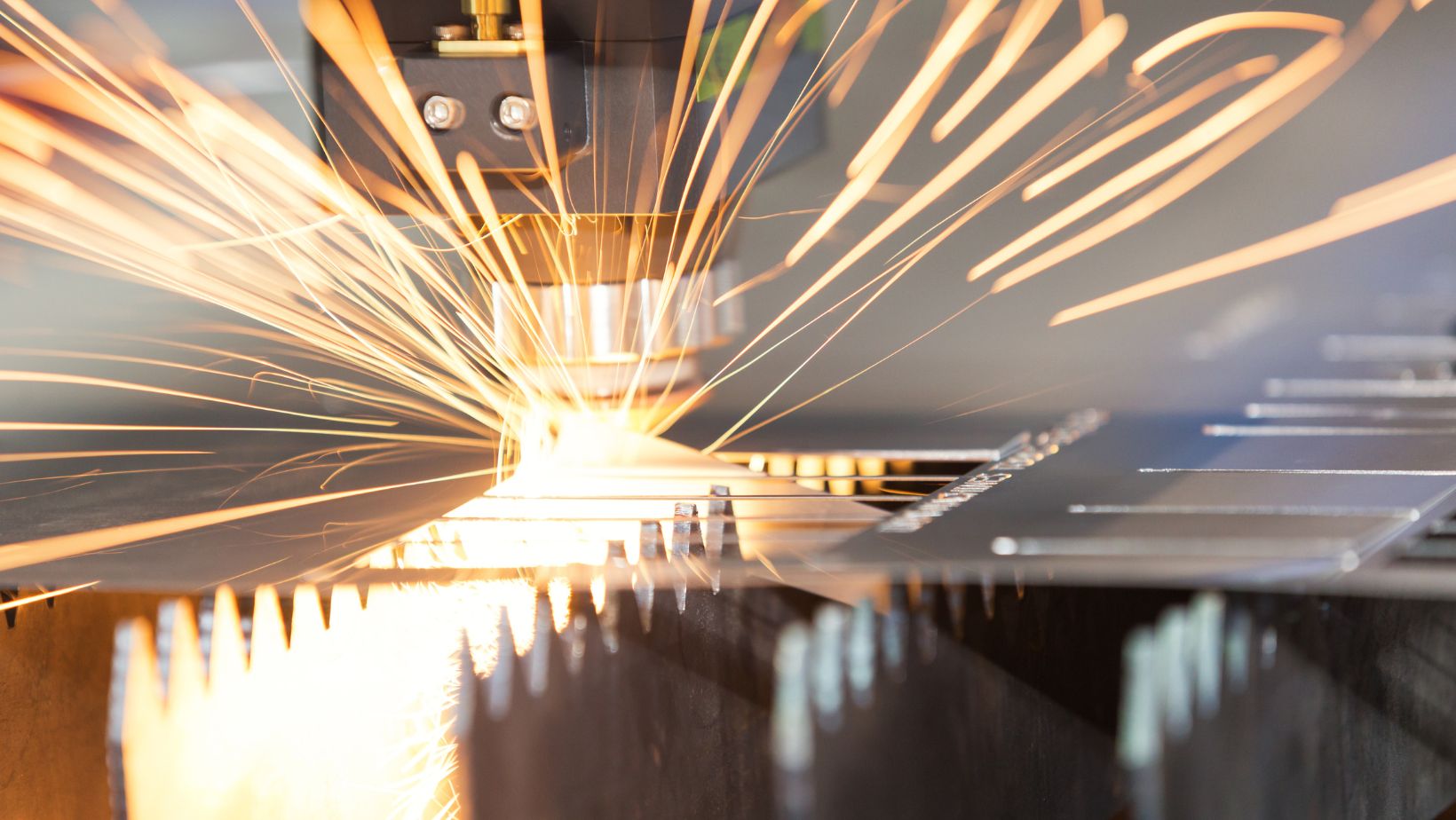

Laser welding has revolutionized numerous industrial and commercial projects with its precision, speed, and versatility, enabling complex tasks to be completed with ease. This advanced technique utilizes focused laser beams to join materials, ensuring minimal distortion and high-quality results. However, finding a service provider that delivers seamless laser welding requires careful consideration of several factors. In this guide, we’ll explore six practical tips to help you make an informed decision for your next project.

Understand the Benefits of Laser Welding

Before you choose a laser welding service, grasp the benefits that laser welding brings to the table. Unlike traditional welding techniques, laser welding offers pinpoint accuracy, reduced distortion, and the ability to work with a wide range of materials. This precision minimizes the need for post-weld clean-up, saving time and money. Laser welding provides superior strength, which is crucial for industrial applications where safety and durability are paramount. Understanding these advantages can help you evaluate whether laser welding is the right choice for your specific project requirements.

Evaluate Technological Capabilities

The effectiveness of laser welding depends on the equipment and technology used. Modern laser welding systems have advanced features that improve efficiency and quality. When choosing a service provider, inquire about the technology they use and whether it is up-to-date. According to EB Industries, laser welding systems are capable of delivering a tremendous amount of energy very quickly and with pinpoint accuracy. This precision ensures minimal material waste, which is particularly important for projects with tight budgets and material constraints. Ensure that the provider you select has access to advanced systems that can meet the specific demands of your project.

Look for Industry-Specific Expertise

Not all laser welding service providers are created equal. Some companies specialize in specific industries, such as automotive, aerospace, or medical device manufacturing. When selecting a provider, consider their experience in your industry.

This expertise ensures that they understand the particular demands of your projects, such as the types of materials used and the required precision levels. For instance, a laser welding company experienced in industrial applications may be better equipped to handle larger, more complex welds, while a provider specializing in smaller commercial projects may offer more cost-effective solutions for your needs.

Check for Quality Assurance Measures

Quality control is crucial in any welding project, especially for large industrial applications. When choosing a laser welding service provider, ask about their quality assurance measures. Do they have certifications such as ISO 9001, which guarantees that their processes meet high-quality standards? How do they ensure the welds are seamless and free from defects? Providers with stringent quality control processes in place will have the systems to prevent errors and ensure each weld meets your specifications. This attention to detail can prevent costly rework and project delays, ultimately saving you time and money.

Consider the Material Capabilities

Different projects require different materials, and laser welding is highly versatile when it comes to working with various metals and alloys. However, not all service providers have experience with every material. Whether your project involves stainless steel, aluminum, titanium, or exotic alloys, make sure that the provider you choose has a proven track record of success with the materials you’re working with.

Understanding the material capabilities of a laser welding provider will ensure that they can handle the unique challenges of your project, delivering strong, seamless welds that meet industry standards.

Compare Pricing and Lead Times

While cost should never be the sole factor in your decision, compare pricing among different providers and understand what you’re paying for. Laser welding can be more expensive than traditional welding techniques due to the advanced technology and precision it offers. However, its long-term benefits, such as stronger and cleaner welds, often outweigh the initial investment. When evaluating providers, look for one that offers transparent pricing without any hidden fees. This transparency ensures you understand where your money is going and helps avoid unexpected costs later on.

A reputable laser welding provider should be able to give you a precise and reliable estimate of how long the work will take and commit to ensuring that the project stays on schedule. Delays can be particularly costly, especially for industrial and commercial projects that operate under tight timelines and strict deadlines. Time overruns can result in increased expenses and missed strategic opportunities. Balancing cost with lead time and quality will help you find the right service provider for your welding needs.

Selecting the right laser welding provider can significantly impact the success of your industrial or commercial project. By focusing on expertise, technological capabilities, and quality assurance, you can ensure a seamless, precise welding process that meets your project’s unique requirements.